Glasdon bollards are available with surface and below-ground fixings. Find out which fixing is right for your permanent, semi-permanent or temporary application.

It may also help to review the following considerations before selecting the bollard fixing for your installation:

1. Will the bollard ever be required to be removed or replaced quickly; in the event of an emergency, for authorised access or due to damage?

If the answer is 'yes' then we would advise that the bollard is installed with a socketed ground fixing system. This allows for the bollard top to be replaced or removed quickly without excavation, leaving the socket in place with a flush ground finish which also enables access if required.

The standard bolt-down fixing can also be used on existing concrete sub-surfaces, while adjustable and fixed depth concrete-in anchors are ideal for fresh concrete sub-surfaces. In the event of removal or replacement, the whole bollard will be required to be unbolted and removed to leave a flush ground finish.

For permanent installations, we offer bollards with a below-ground extended base, anti-ram bollard fixings and fixings for bridges.

2. What depth is available for installation?

The fixing will also depend on the below ground depth that is available. Below-ground fixings are available for depths up to 745mm (Guardsman™ Anti-ram Bollard Fixing). View the range of fixing depths available below.

3. Are you installing a rigid or rebound bollard?

Your choice of bollard material e.g. rigid Durapol™ material or passively safe Impactapol™ material is dependent upon the application and its location.

Where delineation is required in high speed, high-risk areas we would recommend the installation of a self-righting Impactapol material bollard with the compatible LockFast™ Socket System.

Self-righting bollards can also be used in low-speed areas where the risk of impact is high or where there is a history of rigid bollards being regularly damaged or uprooted by vehicle strikes e.g. in tight spaces where vehicles are manoeuvring.

Rigid Durapol bollards are ideal for deterring vehicle access or to create a perimeter with clear delineation.

Please scroll for a general overview of the full range of Glasdon bollard fixings.

If you would like to talk to our road safety experts about your requirements, Live Chat with us on this website or alternatively call us directly on (Freephone) 1800 656 606.

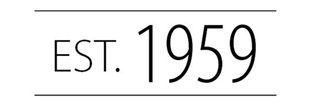

A) LockFast™ Socket System |

||

|---|---|---|

The LockFast Socket System is compatible with passively safe Impactapol and Durapol material bollards.

The socket is designed to absorb the impact of most collisions while leaving the socket itself and surrounding surfaces undamaged. Replacement bollard tops can then be purchased and fitted, quickly and easily, without the need of costly reinstatement or groundworks.

The double-skinned design and square shape of the socket adds strength and prevents twisting during an impact.

The socket is just 350mm deep and has a flat base to cut the time spent installing it.

Made from corrosion-resistant Durapol material, the socket will last for many years.

With the LockFast Socket System bollards are quick and easy to remove and replace, making them ideal for permanent, semi-permanent, or temporary applications.

- Moulded-in product code aids correct bollard top replacement.

- Square shape prevents twisting during a drive through and is easy to pave around.

- Moulded-in arrow and logo aids correct installation.

- Anchor points help to prevent uprooting.

- Flat base - much easier to level.

Safety Notice: If the removal of a bollard creates a safety hazard, we strongly recommend the purchase of a socket blanking cap, which features a slip-resistant finish.

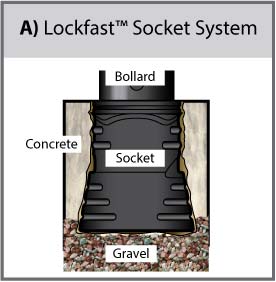

B) Standard Socket System |

||

|---|---|---|

With the standard socket system, Glasdon Durapol bollards are quick and easy to remove and replace in permanent, semi-permanent, or temporary applications.

The 500mm deep socket is double-skinned for added strength and is designed to absorb the impact of most collisions while leaving the socket itself and surrounding surfaces undamaged. Replacement bollard tops can then be purchased and fitted, quickly and easily, without the need of costly reinstatement or groundworks.

Safety Notice: If the removal of a bollard creates a safety hazard, we strongly recommend the purchase of a socket blanking cap, which features a slip-resistant finish.

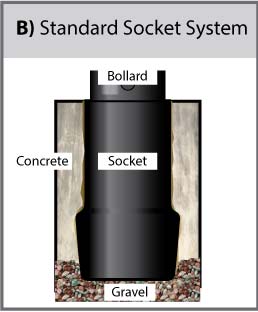

C) Below-ground Extended Base |

||

|---|---|---|

The extended base and horizontal ground fixing peg of the bollard are secured in concrete for permanent installation.

Available with Durapol and Impactapol material bollards.

Please note: some extended base fixings may differ depending on your choice of bollard.

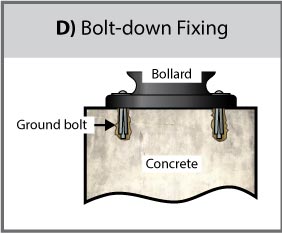

D) Bolt-down Fixing |

||

|---|---|---|

Bolt-down fixings allow a bollard to be installed in under 8 minutes on existing concrete sub-surfaces. This provides a permanent fixing point with a flush ground finish which eliminates trip hazards if the bollard is removed.

This fixing is available with Durapol and Impactapol bollards and is ideal for use where a below-ground installation is restricted or impossible.

Please note: some bolt-down fixings may differ depending on the fixing points of your chosen bollard.

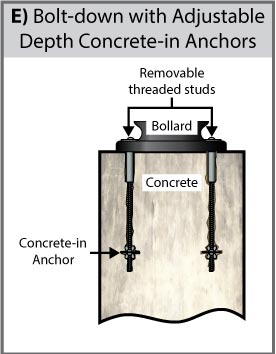

E) Bolt-down Fixings with Adjustable Depth Concrete-in Anchors |

||

|---|---|---|

For additional anchorage and to provide a permanent fixing point for Durapol or Impactapol material bollards, use bolt-down fixings with four adjustable depth concrete-in anchors.

Adjustable depth concrete-in anchors can be used anywhere a fresh concrete sub-surface can be laid, creating a flush ground finish which eliminates trip hazards if the bollard is removed.

Adjustable depth concrete-in anchors can be adjusted to fit depths from 130mm to a maximum depth of 320mm. Please refer to Glasdon bollard installation instructions for individual bollard specification.

Please note: some adjustable depth concrete-in anchor fixings may differ depending on the fixing points of your chosen bollard.

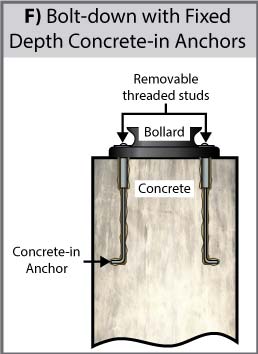

F) Fixed Depth Concrete-in Anchors |

||

|---|---|---|

The two-piece fixed depth concrete-in anchors are suitable for a fresh concrete sub-surface, providing additional anchorage and a permanent fixing point.

Available with Durapol and Impactapol material bollards.

For use in a minimum depth of 250mm. Please refer to Glasdon bollard installation instructions for individual bollard specification.

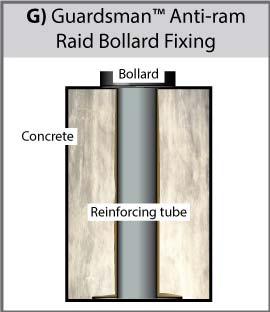

G) Guardsman™ Anti-ram Raid Bollard Fixing |

||

|---|---|---|

A galvanised steel reinforcing tube extends 745mm below ground level, providing an integral root for superb strength and impact resistance. This tube is then filled with concrete. The bollard top is securely attached with hidden coupling bolts. Guardsman bollards are an excellent security feature and have been shown in tests to stop an unladen van dead at speeds of up to 30mph.

Available with selected Durapol material bollards.

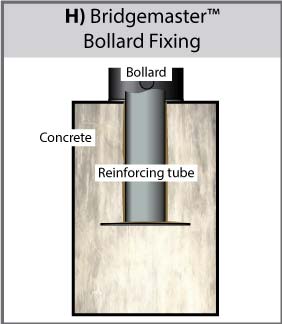

H) Bridgemaster™ Bollard Fixing |

||

|---|---|---|

Ideal for bridges, this fixing can be used where there is an insufficient depth for a socketed bollard, or when there is not a suitable concrete surface/area to bolt-down a surface-fixing bollard.

A galvanised steel reinforcing tube extends 300mm below ground level, providing an integral root for superb strength and ground anchorage. The bollard top is securely attached with hidden coupling bolts.

Installation is quick and easy. Bridgemaster's metal fixing tube is concreted-in and the bollard is attached on the same day.

Available with selected Durapol material bollards.

If you require any further guidance please don't hesitate to talk to our road safety experts via Live Chat or call us on (Freephone) 1800 656 606.